Rau txoj kev khoov ntawmxovxwm nres tshuab , qhov zoo ntawm dabtsi yog khoov tsuas yog nyob ntawm ob qho tseem ceeb ntawm qhov khoov lub kaum sab xis thiab qhov loj me. Thaum dabtsi yog khoov phaj, peb yuav tsum tau xyuam xim rau cov nram qab no yam, thiaj li yuav xyuas kom meej lub dabtsi yog khoov txoj kev loj thiab lub kaum sab xis.

(1) Sab saum toj thiabhauv qabpwm riam tsis yog concentric, uas yuav ua rau muaj kev ua yuam kev hauv kev khoov qhov ntev. Ua ntej yuav khoov, lub puab tsaig pwm yuav tsum tau hloov kho rau hauv nruab nrab.

(2) Tom qab lub tsheb nres txav mus rau sab laug thiab sab xis, qhov chaw txheeb ze ntawm daim ntawv thiab qhov tuag qis tuaj yeem hloov pauv, yog li cuam tshuam rau qhov khoov loj. Txoj hauj lwm nyob deb ntawm lub backstop yuav tsum tau rov ntsuas dua ua ntej khoov.

(3) Tsis txaus parallelism ntawm lub workpiece thiab qis pwm yuav ua rau khoov rebound thiab cuam tshuam lub kaum sab xis. Lub parallelism yuav tsum tau ntsuas thiab kho ua ntej khoov.

(4) Thaum lub kaum sab xis ntawm lub kaum sab xis tsis txaus, qhov kev khoov thib ob yuav raug cuam tshuam. Kev sib sau ntawm kev khoov qhov yuam kev yuav ua rau muaj qhov nce ntawm qhov loj thiab lub kaum sab xis ntawm cov khoom ua haujlwm. Yog li ntawd, nws yog ib qho tseem ceeb tshwj xeeb los xyuas kom meej qhov tseeb ntawm unilateral dabtsi yog khoov.

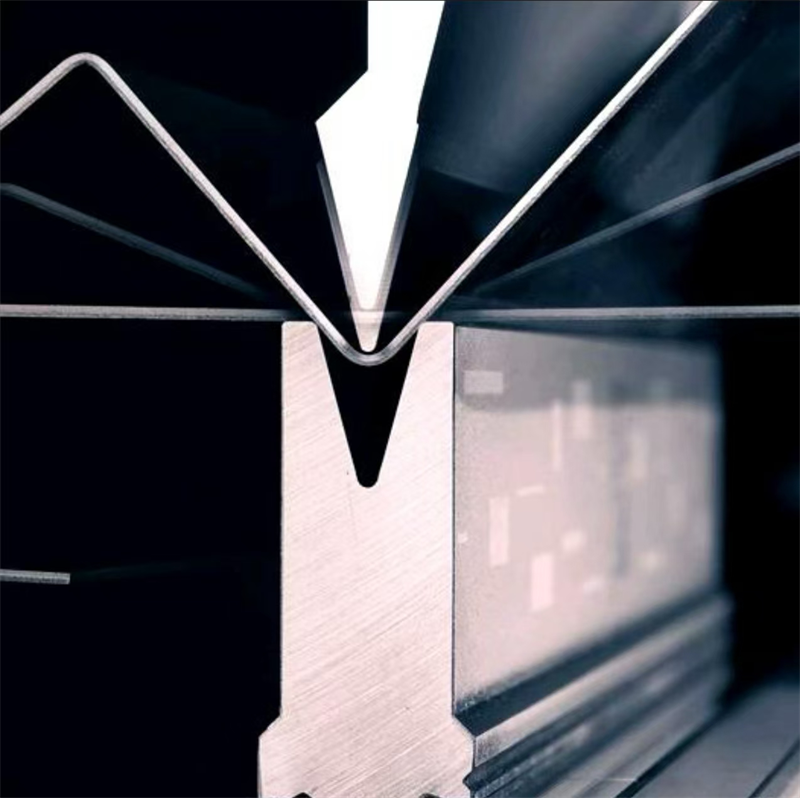

(5) Thaum khoovnrogxovxwm nres tshuab, qhov loj ntawm V-puab zawj ntawm cov pwm qis yog inversely proportional rau qhov khoov siab. Thaum ua cov ntawv hlau ntawm cov thicknesses sib txawv, nws yog ib qho tsim nyog los xaiv qhov tsim nyog V-shaped zawj ntawm qis pwm raws li kev cai, feem ntau 6 mus rau 8 npaug ntawm cov phaj tuab. tsim nyog dua.

(6) Thaum lub workpiece yog khoov rau ntawm lub tshuab dabtsi yog khoov tom qab tsim V-zoo li tus zawj, xyuas kom meej tias cov ntug ntawm lub puab pwm, hauv qab ntug ntawm V-zoo li tus zawj ntawm lub workpiece thiab hauv qab ntug ntawm V-shaped zawj ntawm cov pwm qis yog nyob rau tib lub dav hlau ntsug.

(7) Thaum khoov lub grooved workpiece, txhawm rau tiv thaiv cov cuab yeej clamping, lub kaum sab xis tuag sab saud yuav tsum tau tswj ntawm li 84 °.

(8)Thaum ua ib kawg ntawm cov nias nrestshuab, uas yog, ib sab load, dabtsi yog khoov siab yuav raug cuam tshuam, thiab nws kuj yog ib hom kev puas tsuaj rau lub tshuab cuab yeej, uas yog qhia meej. Thaum sib sau cov pwm, qhov nruab nrab ntawm lub tshuab cuab yeej yuav tsum tau ua kom muaj kev ntxhov siab.

Yog tias koj muaj kev tsis txaus siab txog cov txheej txheem khoov ntawm lubnias nrestshuab, koj tuaj yeem tiv tauj MACRO txhua lub sijhawm. Peb tuaj yeem muab kev qhia rau koj ntawm qhov chaw lossis video qhia kom ua tiav cov txiaj ntsig zoo tshaj plaws thiab kev ua haujlwm zoo hauv koj txoj kev khoov. Txais tos kom sab lajMACROthaum twg los tau.

Post lub sij hawm: Dec-19-2024